Sage 300 ERP provides a very useful feature wherein one can maintain Minimum and Reorder levels for the items. This feature is very helpful when taking orders from customers and committing delivery dates as per the stock availability, In turn help achieve good TAT.

Sage ERP X3 : Plan a step ahead!! Re-order suggestion by Periodic Replenishment method

To enter such information in Sage one needs to navigate to

Inventory Control => I/C Items and Price Lists => Reorder Quantities

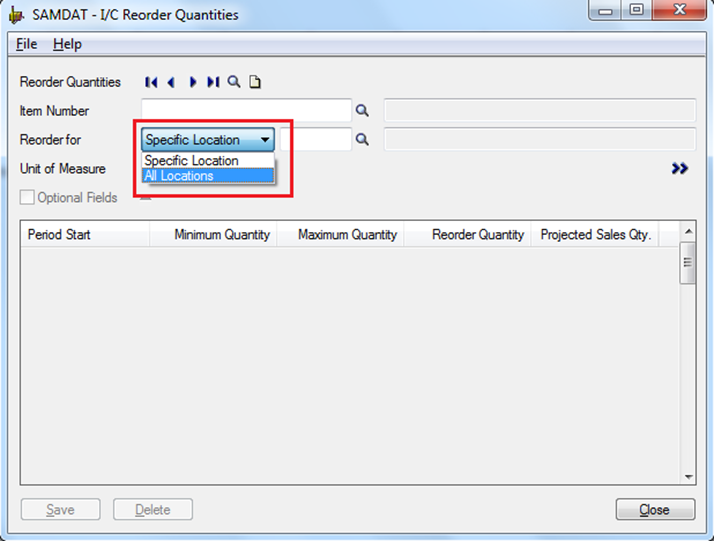

Below is the screenshot of the screen where one needs to update the details.

In this screen one has the option to set Reorder and Minimum Order Quantities for All Locations or for a Specific Location. Assuming the scenario where the user needs to maintain levels for item at individual location, he needs to select the specific location from the dropdown for Reorder for as highlighted in Red above.

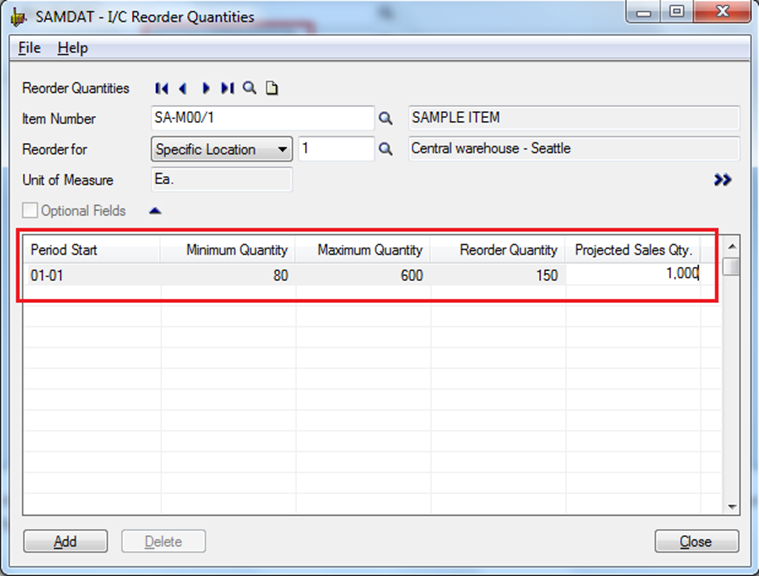

After the selection, you need to enter Period wise Date Wise Minimum Quantity, Maximum Quantity, Reorder Quantity and Projected Sales Quantity. Below is the explanation for the columns present in the grid/table

• Period Start –The Period from which the reorder level belongs to

• Minimum Quantity – The minimum quantity that one wishes to maintain for that particular item in this column

• Maximum Quantity – The maximum quantity that one wishes to maintain for that item so that to know the item is not overstocked in this column.

• Reorder Quantity – Quantity that one needs to order during the specified period when either

a. The number of the items in stock is less than the amount you specified in the Minimum Quantity field, or

b. The projected Sale of the item for the period is greater than the amount of the item in stock.

• Projected Sales Quantity –Targeted Sales Quantity in this column for that particular period

Once the above is fed in; click on Add button to save the data for that particular item.

After entering the details one can go through the reports by navigating for Reorder Quantities as

Inventory Control => I/C Stock Control Reports => Reorder Report

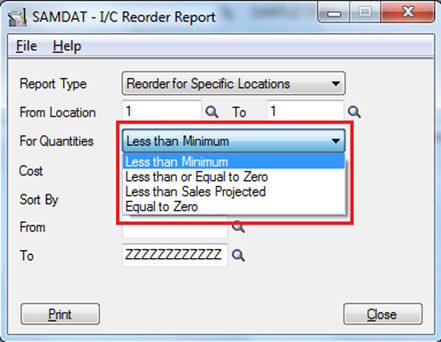

While printing the report one has the option to print report by selecting different levels of Quantities as shown in For Quantities field marked in Red above.

This feature of Sage can be used by both Trading and manufacturing industries.

In Trading, one can get the stock well in advance while taking the orders from customers and hence can meet or commit specific delivery dates and also maintain TAT.

In Manufacturing, one can get the status of the stocks well in advance at the time of doing the Production Planning and can use the resources available accordingly depending on the stock availability of the Raw materials, Packing materials and Consumable items.

Also Read:

1. How to create PO from I/C

2. Purchase Order Reports in Sage 300 ERP

3. Purchase Order Transaction Flow in Sage 300 ERP

4. How to handle Purchase Return in Sage 300 ERP

5. Requisition Approvals in Sage 300 ERP